Corvette Generations:

C1 C2 C3 C4 C5 C6 C7 C8

Corvette: Year by Year

1953 1954 1955 1956 1957 1958 1959 1960 1961 1962 19631964 1965 1966 1967 1968 1969 1970 1971 1972 1973 1974

1975 1976 1977 1978 1979 1980 1981 1982 1983 1984 1985

1986 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996

1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007

2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018

2019 2020 2021 2022 2023 2024 2025

1997 Corvette C5 Chassis,

Suspension and Transaxle Progress

Like the C4, the suspension on the C5 used transverse composite leaf springs on both the front (above left) and rear (right) suspension. The C5 however featured an all new design; none of the suspension parts were carried over from the C4. The system was fully independent and used unequal length A-arms at all four corners, a common race car configuration. Both front and rear suspensions featured anti-sway bars.

The C5 Corvette's floor is constructed using two layers of an aircraft type composite material wrapped around a balsa wood core. The balsa wood helps filter out noise and vibration, and makes the floor 10 times stiffer than the use of composites alone. Numerous "high tech" synthetic fillers were tried, but none matched the stiffness, light weight and damping performance of natural balsa wood.

The chassis side rails were shaped through a process called hydroforming, as opposed to the multiple stampings and welding of the C4 Corvette. The new design was part of the reason why the designers were able to lower the door sill by about four inches. Using seamless tubular steel contributed to the strength of the chassis.

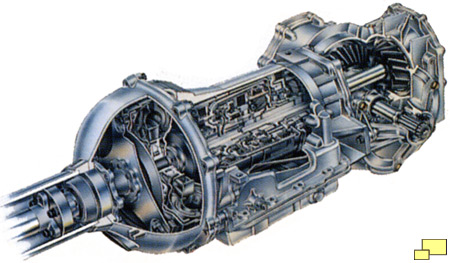

Of the many innovations of the C5, the rear transaxle was at the top of the list. With a transaxle design, the transmission and the differential are located in a combined case at the rear axle. This was the same layout used in the Porsche 944 and Ferrari Daytona. The goal was improved balance; with the weight shifted more to the rear a better front / rear weight distribution was possible. In the case of the C5, weight distribution was 51% front / 49% rear which is close to ideal and an excellent statistic for a front engine car. Another advantage of the rear transaxle was more space in the cockpit area, which resolved a complaint from C4 owners who felt that the footwell areas was too small. Note the torque tube in front of the transaxle and to the right in the above photo. It mechanically coupled the engine to the transaxle which improved handling response, delivering that wonderful and often elusive "sports car feel".

Above: Corvette C5 Torque Tube / Driveline Support Tube

Next: 1997 Corvette Chassis, Family Portrait

1997: A Brave New Corvette World

1997 Corvette Styling: Something Old, Something New